Tire recycling is a corner industry that is increasing in popularity for small business people. Not only does it address the growing issue of tire waste, but it also creates valuable materials for construction. The consistent demand for the outputs means the industry is strong and avoids the dramatic swings common in tech and tourism.

If you’ve ever wondered how to dive into tire recycling but don’t know where to start, this guide is for you. We’ll walk you through the basics of preparing tires for recycling, offering insights along the way.

Understanding the Tire Recycling Process:

Before delving into the specifics of preparing tires for recycling, it’s essential to grasp the fundamentals of the tire recycling process. Tires are composed of various materials, with the primary component being vulcanized rubber with steel and fiber added for strength and durability. The tire recycling machinery separates and processes old tires to produce valuable outputs like tire-derived fuel, rubber mulch, or crumb rubber.

Step 1: Collection and Inspection

The first crucial step in tire recycling is collecting used tires. Tire recyclers establish a network of local automotive shops, tire dealerships, and waste management centers that collect end-of-life tires. Ideally, collectors inspect the tires for any potential contaminants at pick-up. Contaminants include metal or excessive dirt. Clean tires ensure higher-quality end products.

Tip: Offering a convenient collection service to encourage these entities to dispose of their used tires responsibly can increase the outflow of products, shifting the needle towards profit.

Step 2: Storage and Transportation

Once collected, store the tires in a designated area that meets the strict tire storage regulations. Some recyclers invest in storage solutions which keep tires out of the elements to maintain tire integrity.

Transportation is also a key consideration. Tires are heavy and awkward to move by hand. They can also quickly become a hazard if they become dislodged in the transportation process.

Step 3: Debeading

Most tires have steel beads that strengthen the tire and help maintain its shape. Before processing, these beads must be removed through a process called debeading. Alternatively, strong primary shredders can process tires with the bead still on.

Step 4: Shredding

Shredding is the core component of tire recycling, breaking down the tires into smaller pieces for further processing. High-quality shredders are essential for this step, ensuring a uniform and controlled output. The resulting shredded material can be used for various applications, including the production of tire-derived fuel.

Step 5: Steel Separation

After shredding, the tire-derived material is processed to separate steel from rubber. Utilize magnetic separation techniques to extract steel wires, which can be recycled separately. This steel byproduct has its own market value and can contribute to the overall profitability by covering some basic costs.

Step 6: Granulation or Crumbing

Depending on the desired end product, the shredded material can undergo further processing through granulation or crumbing. Crumbing yields fine rubber crumbs that can be used in landscaping, sports fields, or as an additive in asphalt. Further granulation can produce powder rubber, which has numerous applications.

Step 7: Quality Control

Maintain rigorous quality control throughout the tire recycling process. Regularly test the output materials to ensure they meet industry standards. A commitment to quality is fundamental in recycling industries and massively enhances the marketability of your recycled products. It helps build trust with buyers and pays back dividends down the road.

Building a Sustainable Tire Recycling Business:

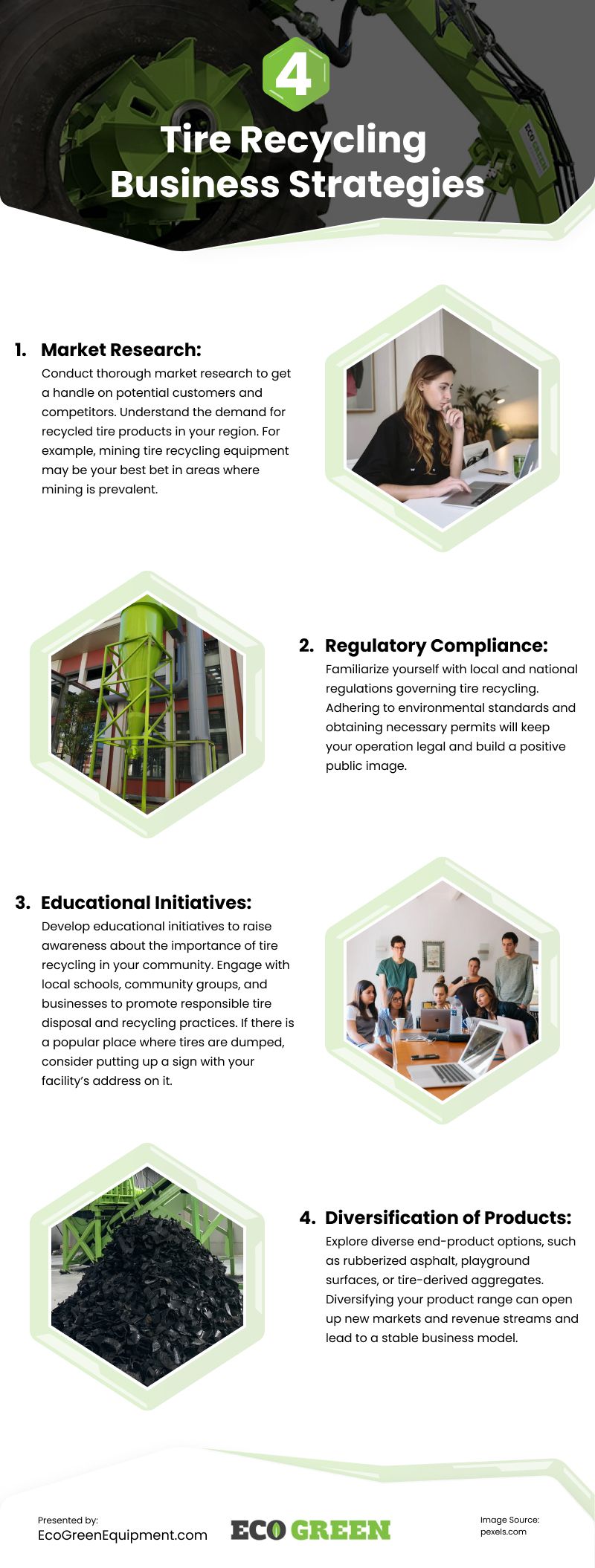

Embarking on a tire recycling business requires more than just understanding the technical aspects. It involves creating a sustainable and profitable enterprise. Consider the following tips to position your business for success:

1. Market Research:

Conduct thorough market research to get a handle on potential customers and competitors. Understand the demand for recycled tire products in your region. For example, mining tire recycling equipment may be your best bet in areas where mining is prevalent.

2. Regulatory Compliance:

Familiarize yourself with local and national regulations governing tire recycling. Adhering to environmental standards and obtaining necessary permits will keep your operation legal and build a positive public image.

3. Educational Initiatives:

Develop educational initiatives to raise awareness about the importance of tire recycling in your community. Engage with local schools, community groups, and businesses to promote responsible tire disposal and recycling practices. If there is a popular place where tires are dumped, consider putting up a sign with your facility’s address on it.

4. Diversification of Products:

Explore diverse end-product options, such as rubberized asphalt, playground surfaces, or tire-derived aggregates. Diversifying your product range can open up new markets and revenue streams and lead to a stable business model.

By understanding the tire recycling process and implementing best practices, you can create a business that reduces tire waste and contributes to a greener future. Remember, if you can nail the tire recycling process for one tire, scaling up to thousands per day will follow easily.

Video

Infographic

Starting a tire recycling business involves more than just understanding the technical aspects; it requires creating a sustainable and profitable enterprise. Consider the following tips for success in this infographic.