Without tires, we would still be using Egyptian sleds to get to work in the morning. While this may be a slight exaggeration, it’s hard to overstate the importance of tires in moving us around. They provide traction and stability for safe driving in almost all vehicles. However, like all things, tires age over time, which can compromise their performance and safety. What causes tire aging? How do older tires affect performance? What happens to tires that need to be retired? Let’s find out.

Causes of Tire Aging

- Oxidation: You might think an unused tire wouldn’t wear out. However, exposure to oxygen and ozone in the atmosphere leads to oxidation, a primary cause of tire aging. This chemical reaction breaks down rubber compounds, resulting in cracks and loss of elasticity. Like bread going stale, except over a much longer timeframe.

- UV Exposure: Ultraviolet (UV) radiation from the sun accelerates tire aging by penetrating the rubber surface and causing it to become brittle. This can lead to cracking and reduced tire performance.

- Heat: High temperatures, whether from prolonged driving or hot climates, can soften the rubber in tires, compromising their structural integrity and accelerating aging. Tire rubber is vulcanized to slow this process down.

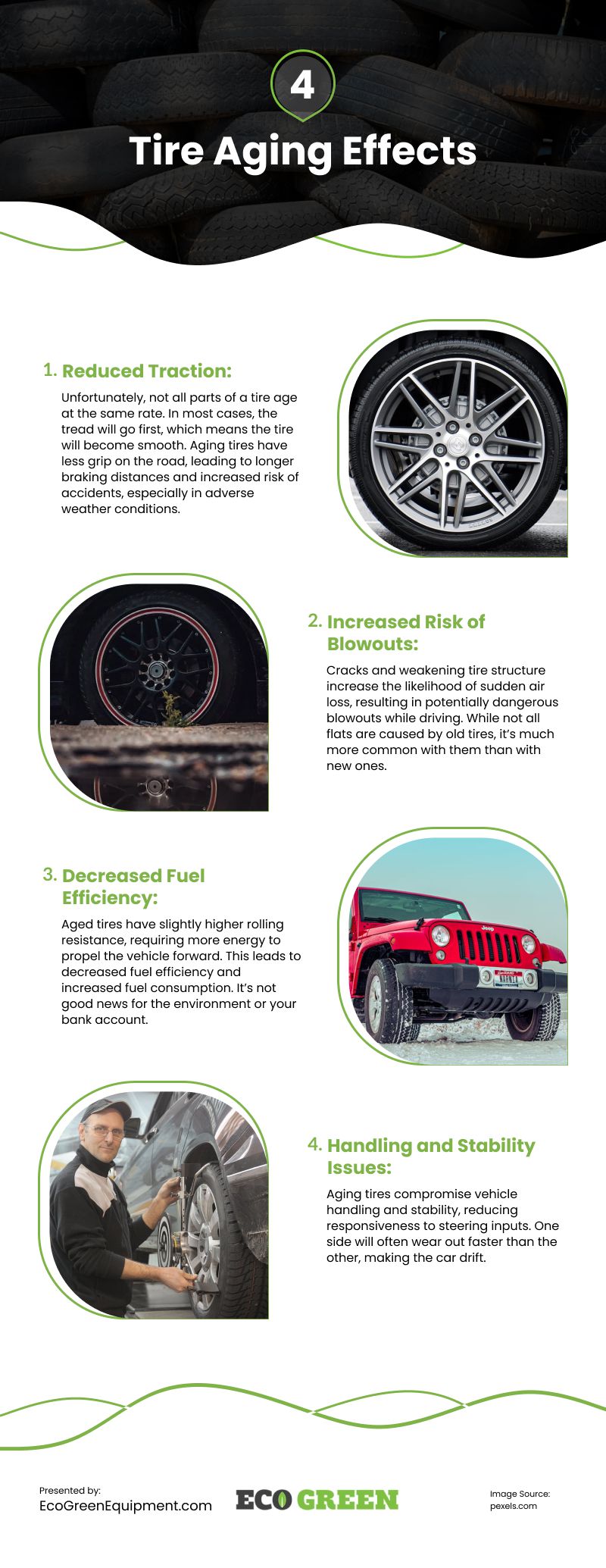

Effects of Tire Aging

With time and use, tires start to show signs of aging which can cause complications.

- Reduced Traction: Unfortunately, not all parts of a tire age at the same rate. In most cases, the tread will go first, which means the tire will become smooth. Aging tires have less grip on the road, leading to longer braking distances and increased risk of accidents, especially in adverse weather conditions.

- Increased Risk of Blowouts: Cracks and weakening tire structure increase the likelihood of sudden air loss, resulting in potentially dangerous blowouts while driving. While not all flats are caused by old tires, it’s much more common with them than with new ones.

- Decreased Fuel Efficiency: Aged tires have slightly higher rolling resistance, requiring more energy to propel the vehicle forward. This leads to decreased fuel efficiency and increased fuel consumption. It’s not good news for the environment or your bank account.

- Handling and Stability Issues: Aging tires compromise vehicle handling and stability, reducing responsiveness to steering inputs. One side will often wear out faster than the other, making the car drift.

Maintenance Tips to Slow Tire Aging

While you can’t feed a tire a healthy diet and tell it to exercise more, you can slow down aging in other ways.

- Regular Inspections: Conduct visual inspections regularly to identify signs of aging, such as cracks, bulges, or uneven wear. Replace compromised tires promptly.

- Proper Inflation: Maintain correct tire pressure according to the manufacturer’s recommendations to prolong tire life and prevent premature aging.

- Avoid Sun Exposure: Park vehicles in shaded areas or use tire covers to protect against UV radiation, minimizing aging caused by sunlight.

- Rotate and Balance Tires: Regular rotation and balancing ensure even wear, extending tire lifespan and improving performance.

- Store Tires Properly: When storing tires, keep them in a cool, dry location away from direct sunlight and heat sources, stored vertically and without heavy objects on top.

The Role of Scrap Tire Recycling

In recent years, the tire recycling industry has grown significantly, thanks to technological advancements and increased awareness that scrap tires are damaging the natural environment. Scrap tire recycling machines process end-of-life tires into valuable materials such as athletic turfs, playground surfaces, and rubber mats, reducing environmental impact and creating sustainable solutions. These machines employ various methods to recycle tires, including:

- Mechanical Shredding: Primary shredders break down tires into smaller pieces, facilitating subsequent processing steps. Shredded tires can be used as a fuel called TDF (Tire-Derived Fuel) to decrease cement kilns’ reliance on mined coal and other fossil fuels.

- Crumb Rubber Production: Tire recycling machines can further process shredded tires into crumb rubber. These crumbs come in various sizes, from large marbles to sand grains. Crumb rubber is used in a wide range of products, including rubberized asphalt and rubber mulch for landscaping.

- Pyrolysis: Pyrolysis machines use high temperatures in an oxygen-free environment to break down tires into oil, gas, and carbon black. This process offers a sustainable method for producing valuable resources from waste tires, with fuel production and manufacturing applications.

Tire aging is a natural process. By understanding the causes and effects of tire aging and implementing proper maintenance practices, drivers can prolong tire lifespan and ensure safety on the road. However, supported by advanced scrap tire recycling machines, tire recyclers turn scrap tires into fuel alternatives or city infrastructure. This important process helps manage end-of-life tires, reduces environmental pollution, and promotes a circular economy. As awareness grows and technology advances, tire recycling will keep rolling forward.

Video

Infographic

Tires provide traction and stability for safe driving. However, they age over time, compromising performance and safety. Learn more about the effects of tire aging in this infographic.