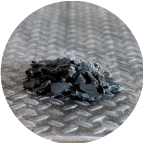

Wire-free Chip

WIRE-FREE CHIPMODELS

Overview

Wire-free Chips or Rubber Mulch are shreds that exit through the second station or secondary shredder of a tire recycling line. At this stage, rough shreds from the primary shredder are processed into a uniform chip with steel removed through a wire cleaning/magnet removal process. These chips are typically 99.9% wire-free. Wire-free chips are typically found in 1 ¼” – 3/8” inch in size.

Wire-free chips have numerous uses from landscaping and playgrounds to engineering applications. An added value of wire-free chips is the ability to remove the steel and sell to buyers. Wire-free mulch is a low-maintenance material for landscapers and homeowners.

Wire-Free Chip Processing:

- Scrap Tire Primary Shreds Reduced to 1 ¼ ” – 3/8 inch chips/mulch

- Takes 80 Scrap Tires to Make One Cubic Yard of Rubber

- Mulch Wire-free Chips have steel removed through a magnet system

- Wire-free Chips can be sold or processed further into crumb rubber

Wire-free Chip Markets:

- Playground Cover and Applications

- Garden Mulch

- Wire-free TDF

- Civil Engineering Applications

- Athletic Turf Infill and Fields Equestrian Products

Wire-free Chip Benefits:

- Cost Effective Alternative to Native Materials

- Virtually Maintenance Free

- Long Useful Life

- Provides steel and rubber for selling

- Diverts Tires from Landfills and Environment